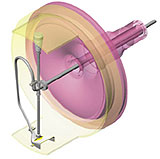

Rotary Scoop Syphon

Designed specifically for non-rimming cylinders, the Kadant Johnson rotary scoop syphon is pre-assembled at the factory for fast and easy installation. Its stainless steel components provide maximum corrosion resistance and offer reliable condensate evacuation for machine speeds up to 275 mpm (900 fpm).

Features

- Stainless steel scoop

- Low clearance syphon gap

- No grinding of scoop required

- Syphon pipe exits back of scoop.

- Stainless steel piping

- Reduced weight

- Pipe connection is 1" DIN and ASA flanged.

- Heavy section walls

- Syphon can be bolted directly to the shell or held by a spring loaded leg.

- Stainless steel spring

- Range of dryer diameters are 1.2 m to 1.5 m (48" to 60").

- Low puddle depth due to large capacity design

- Internal spider not required

Benefits

- Corrosion and erosion resistance, long operating life

- Minimizes blow through

- Optimal condensate evacuation with standard offering for common size dryer

- Lower flow resistance

- Easier installation

- Standard flange, stable mounting, easy installation

- Improved durability

- Mounting flexibility

- Fits standard size dryer cylinders (can be ground to fit smaller diameter dryers)

- Reduced operating torque, reduced stresses on syphon

- Scoop is placed close to dryer head.

Installation

A manhole opening is required to install the unit. Installation is simple, and requires approximately 20-30 minutes per cylinder with the spring-loaded mounting.

Position the assembled syphon unit vertically at the approximate final location inside the dryer with the pick up shoe at the bottom (six-o-clock position). The flanged outlet of the elbow fitting should face the condensate outlet end of the dryer (toward the journal). Place the flanged horizontal pipe inside the dryer. Insert the plain end through the journal and connect the flanged end to the scoop syphon flanged connection.

Check the location of the syphon, making sure that the horizontal pipe extends through the journal the proper distance for the rotary joint installation.

Turn the hex nut to compress the coil spring and to move the counter weight (similar to the pressure plate) up and into contact with the upper part of the dryer shell. Continue to turn the nut until it has reached the weld stop. Tighten the lock nut against the hex nut. The installation is complete.